Electrically Tunable Boiling Heat Transfer

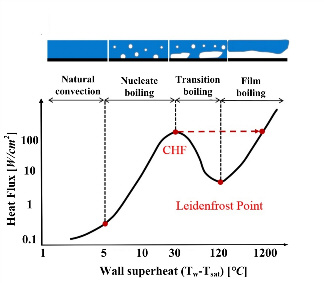

Boiling heat transfer has enormous impact in areas such as electronics cooling, desalination and steam generation. In practice, boiling heat transfer is limited by the formation of a vapor layer at the solid-liquid interface (Leidenfrost effect). This insulating vapor layer severely degrades heat transfer and causes surface dryout, which results in temperature excursions that can cause equipment failure.

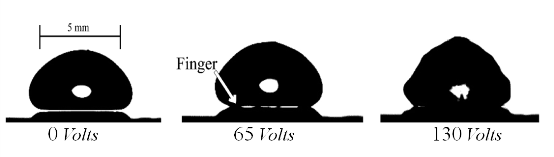

Our recent efforts seek to understand electrostatic suppression of the Leidenfrost state and measure the resulting heat transfer enhancement and dryout prevention benefits. Dryout prevention has been demonstrated at ultrahigh temperatures exceeding 550 °C. More than 10X enhancement in boiling heat transfer has been recorded, which highlights the critical heat flux (CHF) enhancement potential of this concept.

This principle constitutes a disruptive advancement in the field of boiling heat transfer by making the traditional CHF (critical heat flux) limit irrelevant, and enabling electrically tunable boiling heat transfer.